Rapid prototyping is a modern product development method that allows engineers to compress design timelines by iterating faster to reach the final design that can be used in production.

Although 3D printing has become popular as a rapid prototyping method, many industries prefer CNC prototypes to other methods when making models or parts. The applicability of this method depends on the nature of the prototype involved. It is important to consider the purpose of the prototype and the materials of manufacture.

Below are some reasons why CNC machining could be a better option than 3D printing for producing rapid prototypes.

Customisation

Because rapid prototyping solutions allow you to obtain a prototype promptly, you may realise that the prototype you receive isn’t quite what you expected. You can receive a new prototype rapidly to fit your exact requirements without paying a lot of money for many prototypes.

By implementing changes to the digital file, you will be capable of personalising your product prototype. Other approaches are unable to accomplish this; therefore, your prototype may fall short of your expectations. You can schedule a new quick prototyping project for this updated design once you’ve made the necessary adjustments.

Attempts to mimic the finished product

Some models are created merely to mimic the ultimate product’s design, while others mimic both its look and layout. When you employ quick CNC machining, the model will look and perform astonishingly like the end product.

CNC machining can make a single final component or a series of pieces for your prototype following the design. Different rapid prototyping techniques, such as 3D printing, are commonly used to create visual renderings of the prototype or parts.

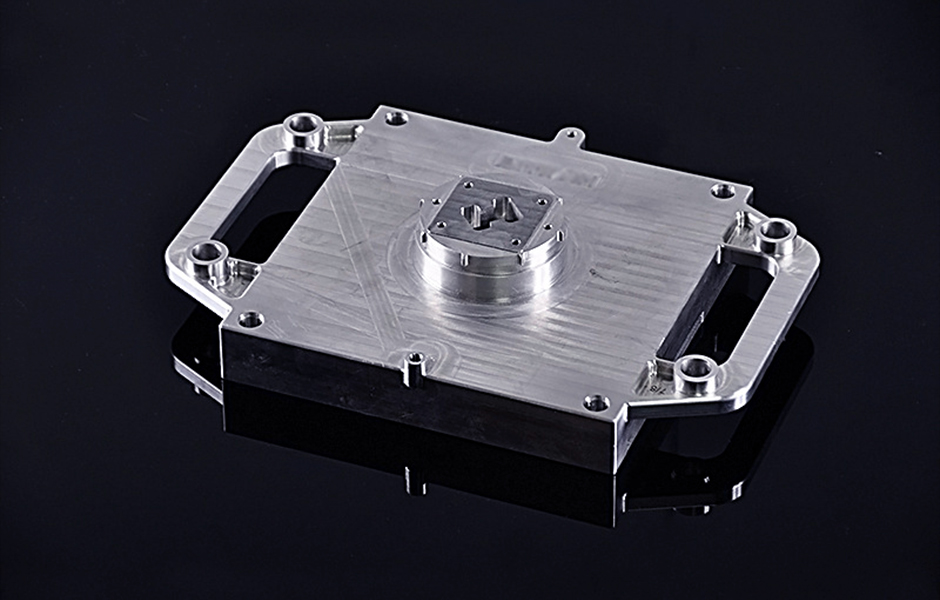

CNC machining, on the other contrary, generates products that are very similar to those produced by injection molding, a standard mass-production technology. Consequently, CNC machining creates long-lasting, functional parts that are remarkably similar to the final, ready-to-sell items.

Exceptional Output

CNC machine equipment can significantly minimise the items’ manufacturing and ancillary time. The CNC machine tools have a wide spindle speed and feed capacity, which allows them to perform efficient cutting with big volumes of material.

High-speed machining is now becoming a reality for CNC machine tools. Parts are moved using CNC machine tools. The semi-finished product’s quick movement and placement, as well as high-speed cutting, shorten the procedure cycle times and boost productivity levels.

There are numerous materials to choose from

Although most 3D printing services employ plastic polymers, CNC machining utilizes a wide variety of materials. The most commonly used materials are CNC aluminium and aluminum alloys. There are, however, a plethora of supplementary resources.

Nonmetallic substances such as plastics, wood, and foam can make CNC machines. This enables a prototype with the appropriate hardness, tensile strength, wear tolerance, and other qualities to be a breeze.

Less labor and cost savings

Unlike other machines that require one person to operate each part individually, to obtain results, two people are required at most. One person can handle each part by using related software, and you need another person to configure the machine to produce the necessary design. Human participation is just to deliver instructions, and then the machine completes the rest of the work. The reduced dependence on people will automatically eliminate the possibility of errors due to human interference.

Since there is no need to hire many people, prototype cnc processing can also ensure that business owners do not have to spend a lot of money on wages. In addition, because it can effectively produce a perfect prototype, it can save the cost of modifying the product after it is put on the market. Because of its speed, people can also quickly reach the execution stage, shorten the production cycle and save costs. You only need to spend a small maintenance fee.

Flexibility

Rapid prototyping is a wonderful option for individuals who would like to test their product before going into mass manufacturing. This procedure is significantly faster than 3D printing or injection molding if you need a prototype right away.

Rapid prototyping with CNC milling offers numerous benefits and results in a high-quality item prototype. Moreover, the excellent quality of the prototype allows you to test your product in a variety of ways before going into total production, enabling you to make changes.

CNC Prototype Machining Service

As you will discover, choosing a company that provides CNC prototyping services will bring you great benefits. At CNC Services China, we provide customers with excellent quality prototype processing services.