Custom machined parts have a growing demand in the industry as the technology nowadays is rapidly improving. Custom machining is always a solution for manufacturing parts that demand special features and unconventional requirements used in various industries.

What is Custom Machining Service?

In short, custom machining is all forms of CNC machining-CNC milling, CNC turning, EDM, etc., whose explicit purpose is to create parts that don’t exist elsewhere.

It refers to custom machining services that meet a client’s specific need for parts. Lately, ordering custom parts from an online machine shop has been trending. This is owing to the high-speed internet network, rapid CAD modeling, and global shipping.

When and Why Is Custom Machining Helpful?

Here are a few instances when and why custom machining becomes the ideal process for your project:

CNC machining uses CAD files that our expert designers create. These CAD files convert data into a program using the software. Since we create the CAD files, we can tailor them to suit any of our client’s needs.

We can work on a wide array of materials when CNC machining. Examples include metals and plastics. This enables us to meet custom machining. Moreover, so many post-finishing methods are applicable that it is somewhat hard to choose. The good thing about this is that our clients have a wider selection choice.

It reduces lead times. Time is a scarce resource that often translates to money. The faster we produce a custom part, the faster it gets to the market. In light of this, we are pushing towards embracing the online quote system. It helps us save a lot of time and get the custom-machined part to the client quickly.

It lacks a minimum order quantity limit. Unlike, injection molding, we can use CNC machining to produce one part. This meets custom machining.

Types Of Custom Machining

When people need customized production parts, it means that these parts may not be standard parts, or have complex structures and unique functions.

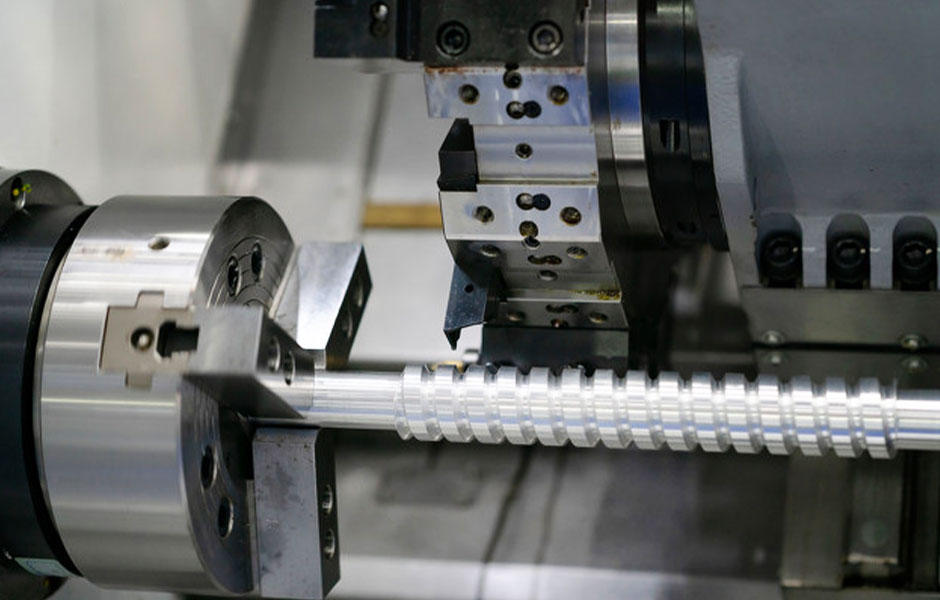

Custom machining may involve many forms of machining, from manual lathes to 5-axis CNC machining centers, from prototype plastic machining to precise metal machining.

The machinery required for a particular project depends on the shape and size of the part and the materials required. For some parts, several different cutting tools are required. At the same time, some customized processing operations do not require CNC equipment at all. For example, a manual milling machine can be used to make simple custom parts such as jigs and fixtures, because the time required to digitally design simple parts can be better utilized elsewhere.

However, in most cases, CNC machining centers are the best choice. They provide precise metal machining and plastic machining and can run semi-automatically, allowing the machinist to perform other tasks freely.

Generally, CNC milling and CNC turning can realize many functions of custom machining. These parts can be contours, grooves, complex rotating shapes, inner holes, threads, biting, etc. However, for complex structures, such as punches, molds, concave-convex molds, fixed plates, discharge plates, micro-hole grooves, narrow grooves, etc., EDM is the best choice for customized machining parts, especially for corners caused by CNC machining The large radius can clear the radius and maintain a right angle.

When custom machining not only requires individualization, high quality becomes more and more important, and the machining workshop is equipped with 5-axis CNC machining capabilities, which can support multi-faceted parts with strict tolerances. This is also called custom precision machining, and you can get the final part with high precision and a short delivery time.

When Need Custom Machining?

- Manufacture Parts With Special Requirements

Your equipment sometimes requires custom-manufactured parts. This may include fast-turnover projects that require additional parts, supplies, and manpower to complete. They can also be custom orders. Projects usually require unique parts that are not in the manufacturer’s catalog.

If you do not have enough resources to carry out these projects, then you will lose business. However, if you have the resources available, you have the potential to undertake special projects and increase efficiency. Custom machining allows you to create “make-to-order” parts and products to keep your operations running and improving.

- Replacement, Discontinued, Or Obsolete Parts

Some companies use equipment and machinery for years or even decades. This means that during maintenance, fixing, or replacement, the parts you need may no longer be on the market. These parts have been produced by the original manufacturer for several years. Even now, it’s still difficult to find used original parts, or even parts manufactured by third parties.

Fortunately, you can take the specifications of these parts and arrange for a company that provides custom processing to produce any quantity you need. Whether it’s a single or a thousand, they can set up the process in a reasonable time, run batches and provide parts to get your machine up and running quickly.

- Handling Difficult Materials

During the production process, certain materials may cause problems. For example, plastics usually require complex CNC processing equipment. Certain metals, such as bronze and stainless steel, may also require specialized parts and equipment. You can’t just follow standard procedures and expect to get the results you need. Therefore, you need specialized equipment, including parts and machinery specially manufactured to perform the process you provide.

- Simplify Production Process And Improve Production Efficiency

With customized equipment, you don’t have to rely on anyone else. You no longer need to order prefabricated parts and deal with suppliers. This means you can save time and money. If there are recent changes to the requirements, the required adjustments can be made as soon as possible. This makes your production process more efficient and has shorter turnaround times.

What Custom Machining Services Do We Offer?

At CNC Services China, we offer one-stop custom machining services. We can use custom parts to check for its visual appeal during the early stages. In addition, we offer low-volume custom machining services. This supports product development in the latter stages before mass production.

CNC MACHINING SERVICE

CNC Services China is a CNC manufacturing and sheet metal fabrication company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services, and stamping services.

CNC Services China offers professional CNC machining and rapid prototyping service for making a wide array of product parts. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every manufacturing size in both low-volume and high-volume productions. Feel free to reach out for a free quote on your project.