Rapid prototyping has revolutionized the product development process in the past few decades. Ever-advancing technology has played a major role in its integration, and businesses in almost all sectors are embracing the possibilities of rapid prototypes.

Having the ability to quickly create a scale model or working version of a product allows businesses to efficiently develop and market a new product. It also expands the scope of manufacturing, allowing for faster exploration and realization of concepts, all while streamlining resources.

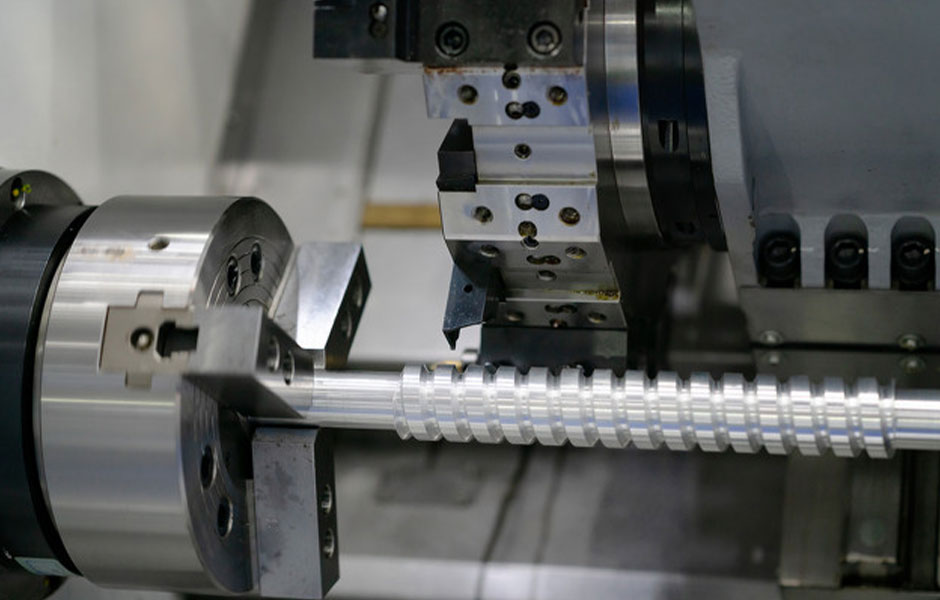

You must manufacture a prototype of your product to evaluate whether your product is fulfilling the intended task and meeting the requirements of the people or not. You can choose from some advanced and revolutionary manufacturing technologies such as CNC machining, 3D printing, and sheet metal fabrication. But for obvious reasons CNC prototype machining is preferred for many obvious reasons like low cost, better quality, a huge variety of materials to choose from, etc.

Creating prototypes of your proposed product before mass producing will help you to compare the feedback of end-users and stockholders and you can improve the product quality before launching.

Benefits Of Using CNC Machining For Rapid Prototyping:

Prototyping Enables You to Get Real-Time Product Feedback

In the planning phase of your product, you would have done a market analysis and collected all the relevant statistics concerning your product. But how about getting real-time feedback from your end consumer by presenting them with the actual samples manufactured using CNC prototype machining? It will be unimaginably considerate before spending resources on an idea of a particular product.

While getting real-time feedback on your product, it is advisable to collect and secure all the valuable opinions and suggestions that people will be giving you. Because recording them will assist you in the further development and R&D of your product, and It will give you a strategic edge over your competitors.

It will assist you to get a better idea of your potential customers’ views about your product. What do they think about it, what improvements do they want and what do they consider to be changed? This sort of critical feedback from the people, who are going to use your product, can be very crucial before you order a mass production and launch it. This extremely important and useful data will let you know the pros and cons of the product in advance. This all will be possible if you manufacture a prototype of your product.

CNC Rapid Prototyping Machines are Accurate

Computer numerical control (CNC) machines are among the most accurate machining technologies today. And this is because most of the CNC machining process is fully automated, eliminating the “human error” factor common in conventional manufacturing processes like injection molding.

A product designer looking to fabricate prototypes only needs to create a 3D CAD model of the design. A machine shop will have no problem manufacturing the part precisely to specification. These machines can make parts to tolerances of ±4 μm, which is more than accurate enough for the vast majority of prototyping requirements.

Time-Saving

CNC machining allows a prototype to be drawn up in record time. It is a popular solution for designers to preview their products in order to make the appropriate decisions. 3D printing is also a technology widely used for prototyping which is an alternative to machining depending on the parts that will be manufactured. It is enough to entrust the model to the platform. Delivery is made within 12 hours after printing and the item is packed well.

Simplified Touch-Up Processes

With rapid prototyping, the prices for rework are no longer exorbitant. The company can afford to fine-tune its results until the entire team is satisfied. Indeed, the improvement of the design can be done in an instant mode. This flexibility is a real advantage for launching the perfect product on the market.

Reduce Manufacturing Defects

Entrusting the 3D printing of its prototypes to a professional means ensuring the quality of the production down to the millimeter. Printers deployed for CNC machining are very precise, regardless of the material used. Startups working in the architecture and art sector are favored by this concept since the details are meticulously worked on.

Attempts To Mimic The Finished Product

Some models are created merely to mimic the ultimate product’s design, while others mimic both its look and layout. When you employ quick CNC machining, the model will look and perform astonishingly like the end product.

CNC machining can make a single final component or a series of pieces for your prototype following the design. Different rapid prototyping techniques, such as 3D printing, are commonly used to create visual renderings of the prototype or parts.

CNC machining, on the other contrary, generates products that are very similar to those produced by injection molding, a standard mass-production technology. Consequently, CNC machining creates long-lasting, functional parts that are remarkably similar to the final, ready-to-sell items.

Go To A Trusted Rapid Prototyping Company

Rapid prototyping companies are especially important for startups because they can advise you on the best technical aspects to get your ideal look. More importantly, whether you are using rapid prototyping equipment for small-batch production, or a high-volume plan that requires injection molding and other production technologies, they will provide you with some suggestions. These factors will make your design easier for mass production.

CNC MACHINING SERVICE

CNC Services China is a CNC manufacturing and sheet metal fabrication company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services, and stamping services.

CNC Services China offers professional CNC machining and rapid prototyping service for making a wide array of product parts. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every manufacturing size in both low-volume and high-volume productions. Feel free to reach out for a free quote on your project.