CNC machines are among the most in-demand manufacturing technologies for metals today primarily because of their high accuracy, precision, and compatibility with a broad range of metals and metal alloys.

However, when it comes to CNC machining copper, there are several things you must keep at the back of your mind. First, you need to understand that pure copper in itself is challenging to manufacture due to its high ductility and high cold workability. Second, a ton of copper-based alloys now exist that offer similar (or even better) properties than pure copper and are relatively easy to fabricate using CNC machines.

You will have no problem choosing an ideal copper alloy for your design requirements as long as you understand the properties, benefits, and drawbacks of each of these alloys.

Advantages of Copper CNC Machining

- Copper CNC machining has been popular for several years now. Copper is machined to produce different small and large parts. The following properties of copper make it an ideal material for CNC machining.

- Copper and its alloys are corrosion resistant, which makes them an ideal choice for applications in various industries where they are exposed to acids, saltwater sprays, and other corrosion-inducing factors.

- Copper is ductile and malleable by nature; however, alloying with elements such as zinc, silicon, tin, nickel, and aluminum improves its machinability.

- Copper is a good conductor of electricity and heat. It is non-sparking and non-magnetic, which makes it a common choice for making electrical connectors, semiconductor parts, and so on. The copper can be easily hot or soldered for creating effective connections.

- Copper parts can be created with a high level of repeatability. This helps us ensure they meet stringent application requirements and specifications.

- The parts made of copper and copper alloys stand high in terms of aesthetic appeal, which makes them an ideal choice for applications where aesthetics may be an important requirement.

Grades Of Copper Materials For CNC Machining

Copper materials are one of the major groups of commercial metals. To a large extent, you’ll find that different grades of copper materials are available for copper part machining. Also, they comprise varying properties suitable for specific machining projects.

Hence, choosing the right material for your machining project can get tricky as it involves several factors.

Even so, identifying the material with properties suitable for your copper parts is the first step to employing machining.

Take a look at the different grades of copper materials for CNC machining below:

Pure Copper

Pure copper materials are usually soft and malleable. The dilute grade of pure copper contains a small amount of various alloying elements. Hence, this helps alter one or more fundamental properties of pure copper to desired forms. Likewise, adding other alloying elements to this copper grade increases its toughness.

Commercial pure copper grades contain about 0.7% total impurities in their composition. You’ll discover that they are designated by UNS numbers C10100 to C13000 based on the added elements and impurity level.

Pure copper is most suitable for manufacturing electrical equipment. They include wiring and motors. Also, this copper grade applies in industrial machinery such as heat exchangers.

Electrolytic Copper

Electrolytic tough-pitch copper originates from cathode copper. Cathode copper means copper refined using electrolysis.

Generally, the process involves filling copper compounds into a solution. Then applying adequate electricity helps purify the copper material. As a result, most electrolytic copper contains lesser impurities than other copper grades.

You’ll find that C11000 is the most prevalent of all electrolytic copper grades. C11000 usually contains less than 50 parts per million metallic impurities, including sulfur. Furthermore, they have high electrical conductivity, up to 100% IACS (International Annealed Copper Standard).

Their exceptional ductility makes them suitable for electrical applications. They include windings, cables, wires, and busbars.

Oxygen-free Copper

Compared to other copper grades, oxygen-free coppers have the highest purity. They also contain little to no oxygen content. In most cases, oxygen-free copper grades include many high-conductivity electrical copper components. Yet, C10100 and C10200 are the most common.

- C10100, known as Oxygen-free electronic (OFE), is a pure copper with about 0.0005% oxygen content. More so, it is the most expensive of these copper grades.

- C10200, also called Oxygen-free (OF), contains about 0.001% oxygen. It also has high electrical conductivity having at least 100% IACS, which is no better than electrolytic copper materials.

These oxygen-free copper materials get manufactured by induction melting using high-quality cathode copper. In this manufacturing process, cathode copper gets melted under non-oxidizing conditions provided by graphite bath covering. Thus, this helps reduce the hydrogen content in the working atmosphere.

Oxygen-free coppers are most suitable for high vacuum electronics due to their high conductivity. They include transmitter tubes and glass-to-metal seals.

Free-Machining Coppers

This copper material comprises various alloying elements. The notable elements include nickel, tin, phosphorus, and zinc. The presence of these elements helps increase the machinability of this copper grade.

Furthermore, free-machining copper materials comprise copper alloys such as bronze and brass. Take note of the following:

Bronze is an alloy of copper, tin, and phosphorus well-known for its hardness and impact strength.

Brass is an alloy of copper and zinc with exceptional workability and corrosion resistance.

Free-machining copper materials are suitable for a wide range of copper parts machining. They include coins, torches, machined electrical components, gears, bearings, automotive hydraulics, etc.

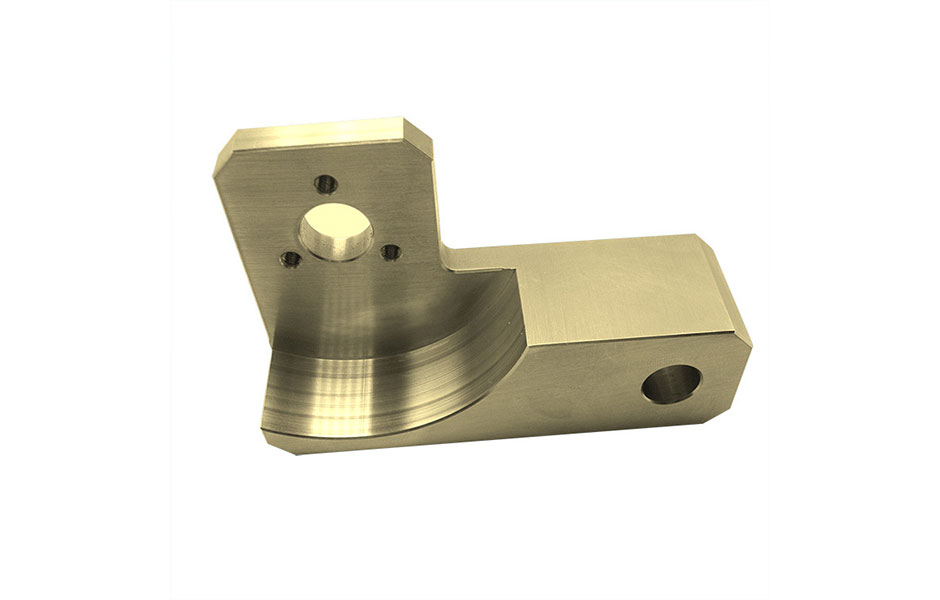

CNC Machining Copper and Copper Alloys

Copper alloys offer a lot of desirable properties that make them ideal for a broad range of applications. But even after choosing the ideal copper alloy for your product design, the success of your manufacturing project still depends on your manufacturer.

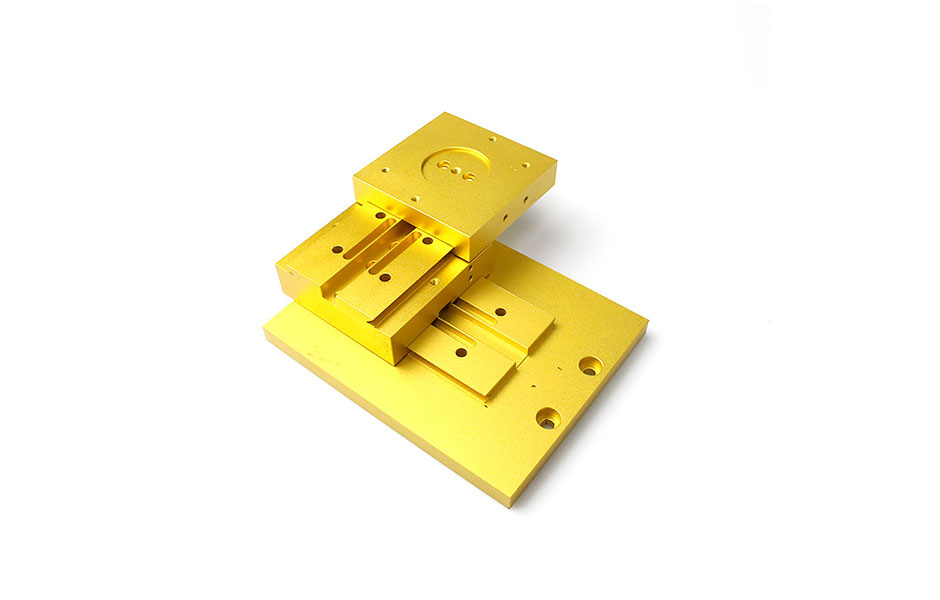

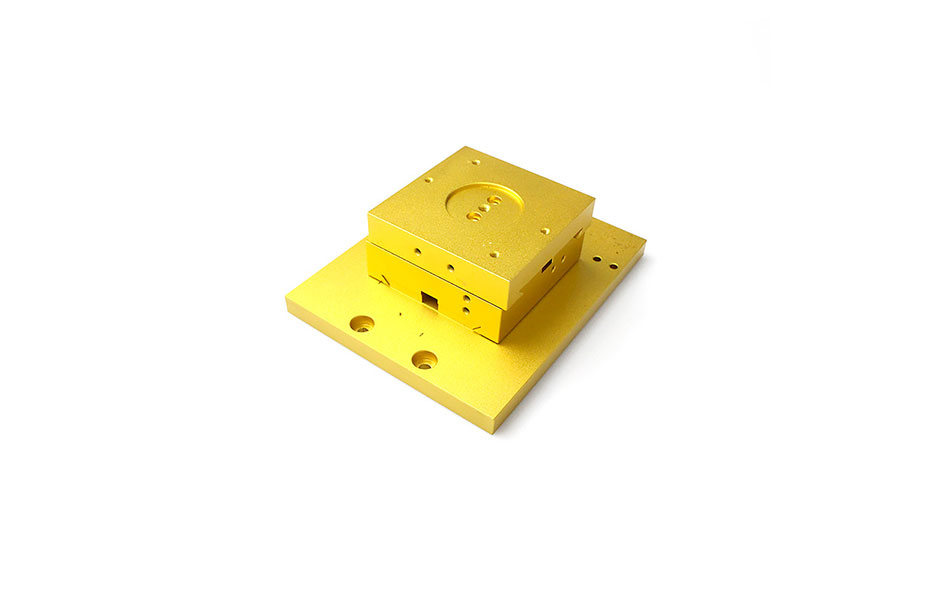

CNC MACHINING SERVICE

CNC Services China is a CNC manufacturing and sheet metal fabrication company, including CNC machining services, CNC milling services, CNC turning services, laser cutting services, and stamping services.

CNC Services China offers professional CNC machining and rapid prototyping service for making a wide array of product parts. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every manufacturing size in both low-volume and high-volume productions. Feel free to reach out for a free quote on your project.